3D Printing for Roman Coin Replicas: A Modern Approach

For the hobbyist eager to recreate the allure of ancient Roman coinage, traditional methods of mold-making and casting have long been the standard. But with the rise of accessible 3D printing technology, a new and increasingly popular option has emerged: using 3D printing to create coin molds and even, in some cases, direct replicas. This article explores this modern approach, detailing the advantages, disadvantages, and essential best practices for those wanting to combine ancient history with cutting-edge craft techniques.

The Appeal of 3D Printing for Coin Replication

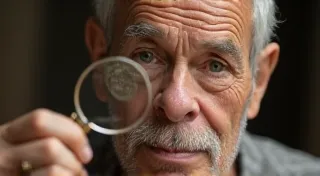

Historically, creating accurate coin replicas involved carving molds from wax or clay, a laborious and skill-intensive process. 3D printing offers a significant leap forward. It provides the potential for unparalleled accuracy, repeatability, and design freedom. Imagine being able to create molds based on high-resolution scans of original coins, faithfully reproducing intricate details that would be incredibly challenging to achieve by hand. The possibility of experimenting with different design variations and even creating entirely new coin "designs" inspired by Roman motifs is another exciting prospect.

Methods: Molds vs. Direct Printing

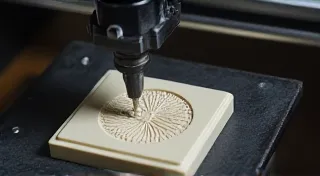

There are two primary ways 3D printing is employed in the coin replica process:

- Mold Creation: This is the more common and generally recommended approach. You use a 3D printer to create a mold that can then be used with traditional metal casting techniques (like lost-wax casting or sand casting) using materials such as bronze or pewter. This allows you to achieve the authentic look and feel of a Roman coin.

- Direct Printing (Resin or Filament): While technically possible, directly printing coins with filament (PLA, ABS, etc.) or resin is less desirable. The resulting coins lack the metallic feel and appearance of true Roman coinage. The material properties are also far different, leading to a product that is more of a novelty item than an accurate replica.

Pros and Cons of 3D Printing Coin Molds

Pros:

- Accuracy: 3D printing enables exceptionally high levels of detail reproduction.

- Repeatability: Consistently produce identical molds and, subsequently, replicas.

- Design Freedom: Easily modify existing designs or create entirely new variations.

- Speed: Faster than traditional mold-making techniques, especially for complex designs.

- Accessibility: Affordable 3D printers are readily available.

Cons:

- Initial Investment: Purchasing a 3D printer represents an upfront cost.

- Material Costs: Filament or resin usage adds ongoing expenses.

- Learning Curve: Requires familiarity with 3D printing software and printer operation.

- Post-Processing: Molds often require post-processing (sanding, polishing) to ensure smooth casting surfaces.

- Printer Resolution Limits: Even high-resolution printers have limitations in replicating extremely fine details.

Best Practices for Success

- Model Selection/Creation: Use high-resolution digital models of Roman coins. If creating your own, ensure accuracy and attention to detail.

- Printer Choice: Resin printers generally offer higher resolution than filament printers, making them preferable for capturing fine details.

- Material Selection: Choose a durable material for your molds that can withstand repeated use with molten metal. Ceramic-filled resins or specialized high-temperature filaments are good options.

- Orientation & Support Structures: Carefully consider the orientation of the model during printing to minimize support structure requirements and ensure accurate detail reproduction.

- Post-Processing: Thoroughly clean and polish your molds before casting to remove any residue or imperfections.

- Casting Technique: Employ proper casting techniques to prevent damage to the mold and ensure a high-quality replica.

The Future of Coin Replication

The intersection of ancient history and modern technology is opening exciting new avenues for coin replication. As 3D printing technology continues to advance – with improvements in resolution, material properties, and ease of use – we can expect even more sophisticated and accessible methods for creating accurate and beautiful replicas of Roman coinage. The potential for recreating lost or rare coins, experimenting with historical designs, and educating future generations about Roman history is immense. By embracing these new approaches, hobbyists and researchers alike can unlock a deeper appreciation for the artistry and significance of Roman coinage.