Tools & Equipment: A Budget-Friendly Setup for Roman Coin Replicas

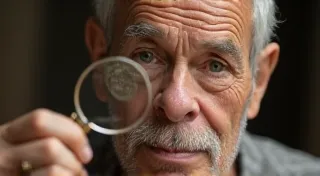

Creating accurate replicas of Roman coins is a fascinating craft, blending history, artistry, and a little bit of metalworking. Many aspiring replicators are intimidated by the perceived cost of the necessary tools. However, you don't need a professional workshop to get started! This article outlines a budget-friendly setup allowing you to create impressive Roman coin replicas without breaking the bank.

The Essentials: What You Really Need

Let's break down the crucial tools into categories – molding, casting, and finishing – and explore affordable options for each. We'll focus on beginner-friendly techniques that prioritize cost-effectiveness over speed or industrial-scale production.

Molding: Capturing the Original Design

The mold is your template, the foundation for a faithful replica. While professional coin-making utilizes high-precision CNC milling, we're focusing on simpler, cheaper methods.

- Silicone Rubber: This is your primary molding material. A small container of silicone rubber (look for "potting silicone" or "mold making silicone") is enough to create multiple molds. Prices vary, but you can often find decent quality options for $20-$40.

- Release Agent: Essential to separate the silicone from the original coin (or a master model if you have one). Petroleum jelly or a commercial release agent will do.

- Container/Mold Box: A simple plastic container or even a cardboard box lined with plastic sheeting will work as a mold box to contain your silicone.

Casting: Bringing the Replica to Life

Metal casting can seem daunting, but there are beginner-friendly methods that avoid the need for expensive furnaces or kilns.

- Lost Wax Casting (Simplified): While true lost wax casting is complex, a simplified version using readily available materials is suitable for beginners.

- Aluminum Foil/Clay Method: A simple technique where molten metal is poured into a mold created by wrapping aluminum foil around the original coin and then embedding it in clay. This yields surprisingly accurate results. You'll need a heat source – a propane torch is common (but be extremely careful!).

- Metal Source: Aluminum is the most accessible and forgiving metal to start with. Scrap aluminum (like soda cans – properly cleaned!) can be recycled.

- Crucible (Small): A small crucible, specifically designed for metal melting, is necessary for safe and controlled melting.

Finishing: Bringing Out the Details

Once the metal has cooled and solidified, the replica needs some finishing touches to remove imperfections and highlight the details.

- Files: A set of small, needle files is essential for removing flash and refining the edges of the replica.

- Sandpaper: A range of grits, from coarse to fine, allows you to smooth the surface and remove any remaining imperfections.

- Polishing Compound: Polishing compound, along with a soft cloth, helps bring out the shine and detail of the replica.

A Budget Breakdown (Approximate)

- Silicone Rubber: $20 - $40

- Release Agent: $5 - $10

- Crucible: $15 - $30

- Needle Files: $10 - $20

- Sandpaper Assortment: $5 - $15

- Polishing Compound: $5 - $10

- Propane Torch (if needed): $20 - $50 (can often be borrowed)

Total Estimated Cost: $80 - $180 (depending on existing tools)

Important Safety Considerations

Working with molten metal carries inherent risks. Always prioritize safety:

- Wear appropriate safety gear: eye protection (goggles or face shield), gloves (heat resistant), and old clothing.

- Work in a well-ventilated area.

- Have a fire extinguisher readily available.

- Research and understand the specific risks associated with the materials and tools you're using.

- Start small and practice with inexpensive metals like aluminum before attempting more valuable materials.

Conclusion

Creating Roman coin replicas can be a rewarding and accessible hobby. By focusing on budget-friendly materials and techniques, you can embark on this fascinating journey without breaking the bank. Remember to prioritize safety, research thoroughly, and enjoy the process of bringing history to life!